CHP UNITS FOR THE ENERGY SUPPLY OF INDUSTRIAL ENTERPRISES

During the transition to renewable energies, concepts for the independent and decentralised generation of useful energy are gaining increasing attention. In so doing, energy efficiency, flexibility and resource conservation are crucial criteria. The decentralisation of energy generation by means of combined heat and power generation represents a major potential in this respect. CHP units are gaining increasing significance in the context of a decentralised energy supply of industrial enterprises that is independent from the energy policy framework conditions.

Together we will find the energy solution that is right for you.

COMBINED HEAT AND POWER

The combined heat and power generation, also known as CHP, is the simultaneous conversion of primary energy (in the form of fuel) into thermal and mechanical (as basis for the extraction of electrical) useful energy in a technical system. This type of energy conversion is characterised by high degrees of utilisation, that is, the very efficient conversion of fuel into useful energy.

ADVANTAGES ACHIEVED WITH CHP

Compared to the separate power and heat generation, this combined generation of power and heat is:

ECOLOGICAL

- Efficiency-boosting

- CO2-reducing

- Sustainable

- Environmentally friendly

- Resource-conserving

ECONOMICAL

- Dynamic

- Independent

- Cost-reducing

- Pro-competitive

- Reliable in terms of supply

The advantages of this procedure are also reflected in the energy and climate policy goals of the federal government, which aims to increase the proportion of CHP in the power generation to 25% by 2020.

In the context of the energy transition, the CHP represents a crucial pillar and the link between a volatile energy market and a heating market that can be better planned.

CHP UNITS

The cogeneration of heat and power can be realised among other things in CHP units, also called cogeneration units. By definition, the main principle is always the simultaneous extraction of thermal and mechanical energy in a technical system. CHP units on the basis of efficient internal combustion engines have been used successfully for years. In particular CHP units powered by natural gas are used most often for the decentralised CHP generation.

Technology and functions of a

CHP unit

In cogeneration units, an internal combustion engine – a diesel or petrol engine – is used to power a generator to generate power. The established engine technology originated in the industrial engine and ship building industry. The lion’s share of the waste gas heat as well as the heat accumulated in the engine's cooling water and in the oil cooler is extracted as useful heat by way of heat exchangers.

The shares of waste gas, cooling water and engine oil heat are dependent on the engine power. With large engines, the heat ratios are almost identical, while the cooling water and engine oil heat is greater with small engines.

The waste gas heat is available at a temperature level of approx. 500°C. At the outlet of the waste gas heat exchanger, the temperature of the waste gases is normally about 120°C. The waste gases in the CHP unit can be cooled further by means of an additional condensing heat exchanger. The thermal utilisation factor can be increased by using this heat of condensation.

The temperature of the accumulated heat from the engine cooling water and the oil cooler ranges between approx. 85-90°C and is known as low-temperature heat (=LT heat). Care should be taken that the return flow temperature for cooling the engine should not exceed 70°C whenever possible. Higher temperatures at the secondary cooling cycle are possible if so-called hot-cooled engines are used in combined heat and power units.

Two variants exist for the heat extraction from cogeneration units:

Single-stage heat extraction

The two heat sources – engine cooling water and exhaust gas heat – are transferred in the CHP unit via a heat exchanger to a shared secondary water cycle. The flow temperature of the secondary cycle is usually close to 90°C. The return flow temperature must not exceed 70°C. If the return flow temperature exceeds a defined limit, the excess heat can be supplied to suitable refrigeration facilities.

Double-stage heat extraction

Two independent secondary cycles in the cogeneration unit are required for the separate extraction of the two heat sources. In so doing, the low-temperature heat from the engine cooling water and oil cooler is extracted by way of a heat exchanger. As with the single-stage heat extraction, the return flow temperature must not exceed a defined limit of approx. 70°C. The flow usually has a temperature of approx. 85°C. The energy contained in the exhaust gas can be used for the generation of steam, heat transfer oil or hot water by means of a waste heat recovery boiler. The use of the exhaust gas in direct or indirect drying processes represents another possible application.

Depending on the type of engine used in the cogeneration unit, the following fuels can be used:

- Heating oil

- Palm oil

- Liquid gas

- Natural gas

- Sewage gas

- Landfill gas

- Biogas

- Coke oven gas

- Residual production gases

- A combination of different fuels

POWER GENERATION AND

CONNECTION TO THE GRID

Synchronous generators are used if greater capacities are required or if the CHP unit is to be operated in isolation, that is, without being connected to the public grid. The technically more elaborate design of the synchronous generator requires the use of so-called synchronisation equipment used for the adaptation to the frequency of the grid to be connected. Thanks to the synchronous generator’s ability to draw as well as supply reactive power from and to the grid, the use of such a generator in the cogeneration unit can contribute to the reduction of the reactive power costs.

As an alternative to off-grid operation alone, the CHP unit may also be operated in parallel with the grid. This means that the cogeneration unit is still connected to the public power grid and that

one hundred percent of the generated electrical power is fed into the grid or

one hundred percent is used to cover own requirements and the additionally required power is covered by electrical power from the public grid, or

it is partly used to cover own requirements or fed into the public grid, depending on the development of the demand for electrical power.

The considered operating mode is dependent on the economic conditions, which must be contrasted with the grid supply and the costs for the procurement from the public grid. These points should be examined carefully during the pre-planning phase.

OPERATING MODES

OF A CHP SYSTEM

There are essentially three different control modes for CHP systems. They are the

- heat-led control

- power-led control

- line-commutated control

With the heat-led control, the operation of the CHP system is determined by the required heat. The CHP system follows the heat requirements and is therefore partly in part-load operation. The highest utilisation factors are achieved in this way, because no heat is unnecessarily released into the environment.

However, the heat-led control does not produce the greatest possible amount of electricity. A customer's energy requirements are generally greater than the installed electrical power. Because the price to purchase power from the grid is usually higher than the costs for generating power in a CHP system, it may be worthwhile to release part of the generated heat into the environment in order to increase the power generation. If the control of the CHP system is determined by the customer’s energy requirements, it is known as power-led control. In that case, the CHP system is only controlled in part-load operation if the power requirements are lower than the installed power of the CHP system. With the power-led control, the CHP system covers the greatest possible proportion of the power requirements. Still, the release of any amount of heat into the environment is not permitted with the power-led control either. Compliance with the high-efficiency criterion throughout the respective year and/or month is compulsory, based on which at least 70% of the fuel-derived energy must be converted into useful energy, that is, power and heat. Failing that, tax benefits with respect to the energy tax may not be claimed.

The line-commutated control is gaining increasing importance. With the line-commutated control, the plant operation is not controlled by the customer’s requirements, but by the grid requirements. The controls of several CHP systems are interconnected to create so-called virtual power stations. When the power demand in the grid is greater than the currently generated electrical power of the cogeneration unit, several CHP systems in the virtual power station increase their electrical power, thereby supporting the grid frequency. If the power available in the grid exceeds the demand, the CHP systems in the virtual power station reduce their output. With the line-commutated control, the CHP systems thus support the grid stability by supplying balancing energy. With the further expansion of renewable energies, the line-commutated control is expected to gain increasing relevance.

| Control | Principle | Advantages | Disadvantages | ||

|---|---|---|---|---|---|

| Heat-led |

Determined by the demand for heat |

Highest degree of fuel utilisation |

Lower power generation |

||

| Power-led |

Determined by the demand for power |

Highest degree of power generation |

|

||

| Line-commutated |

Determined by the grid requirements |

Contribution to the stability of the power grid |

LEGAL

FRAMEWORK CONDITIONS

The legal framework conditions applicable to CHP systems are multifaceted. The most relevant laws are:

the Federal Immisson Control Act [Bundes - Immissionsschutzgesetz, BImSchG]

the Combined Heat and Power Act [Kraft-Wärme-Kopplungsgesetz, KWKG]

the Renewable Energy Sources Act [Erneuerbare Energien Gesetz, EEG]

the Energy Tax Act [Energiesteuergesetz, EnergieStG]

The purpose of the BImSchG is to protect the environment, human beings, animals or any other material goods against harmful effects on the environment and to prevent such effects. If the approval pursuant to the BImSchG is required for the system, the Act also stipulates the compulsory precautions that need to be taken in order to achieve a high level of protection against harmful effects on the environment, whether caused directly or indirectly by the system.

The Combined Heat and Power Act (KWKG) sets forth that the operator of a CHP system is entitled to a bonus, known as CHP bonus, for every kilowatt hour of power it generates. Depending on the electrical power, the promotion is limited to a specified duration.

The goal of the Renewable Energy Sources Act or EEG is to promote the generation of energy in a sustainable fashion, with the protection of the environment and climate, the conservation of fossil raw materials, the economic costs for the energy supply and further development of renewable energy supply technologies in mind. The federal government aims to increase the proportion of renewable energies to 80% of the gross power consumption of the Federal Republic of Germany by 2050.

We live partnership –

Find your contact person

Find your contact person

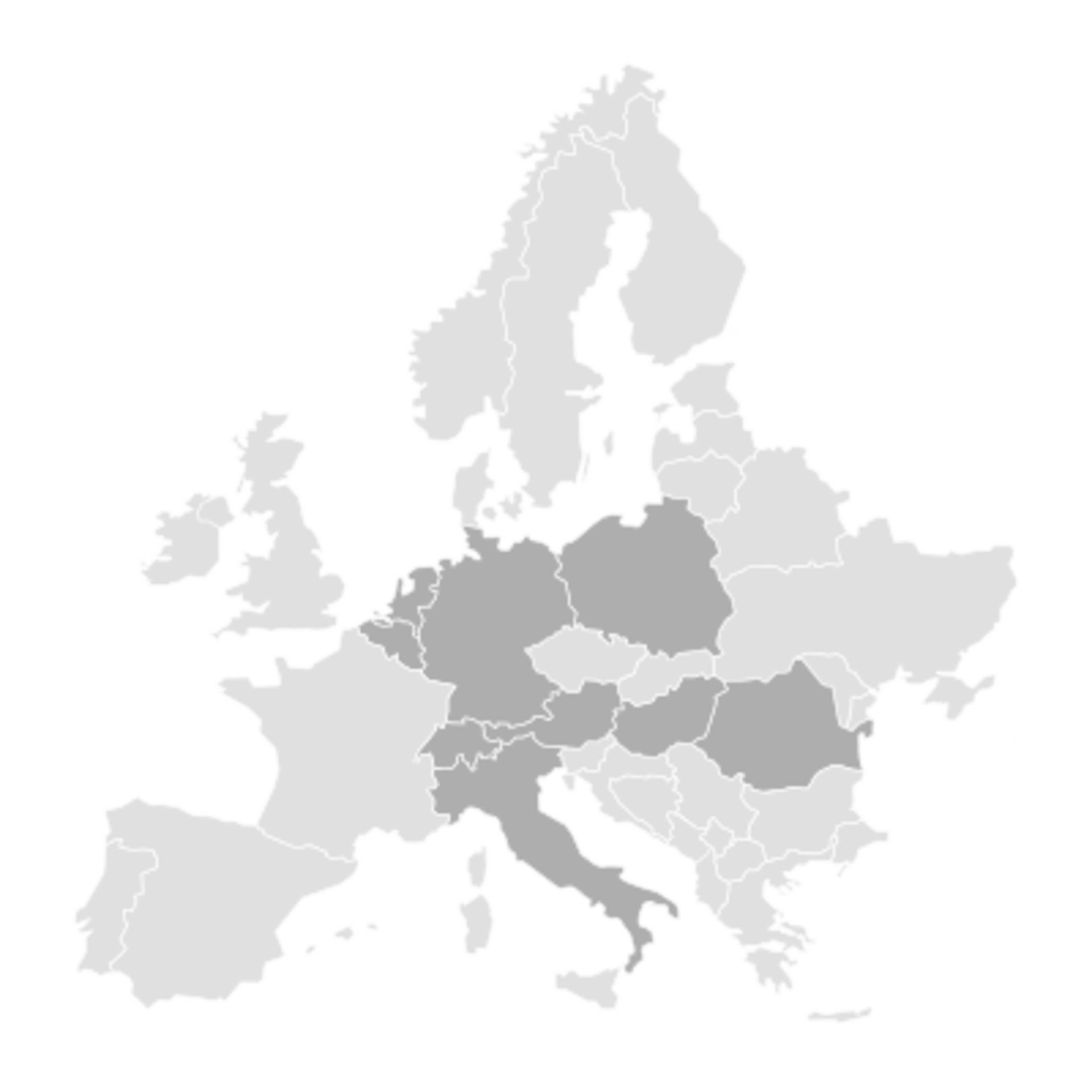

With far over 70 locations in Europe, we are always close to you.

Contact us. We are there for you.